Curb Machines By Curb Dog Equipment

At Curb Dog Equipment, we feel that we offer the best curb machines & slipforming products available today, delivering the best curbing solution/experience in its class. Yet, at the end of the day, lack of knowledge and familiarity with various aspects of concrete and site preparation can diminish that experience and truly frustrate you as the owner of a new PCM machine. We know that our curb machines will do what they are supposed to do…will you and your crew be able to do the same? Our curb machines are exceedingly capable but are not themselves a “magic bullet”. Experienced finishers, a dedicated operator and a complete understanding of concrete and site variables complete the equation to success with your curb machine. Making the commitment to your new Curb Machine as well as your support personnel will truly put you miles ahead of your competition for years to come!

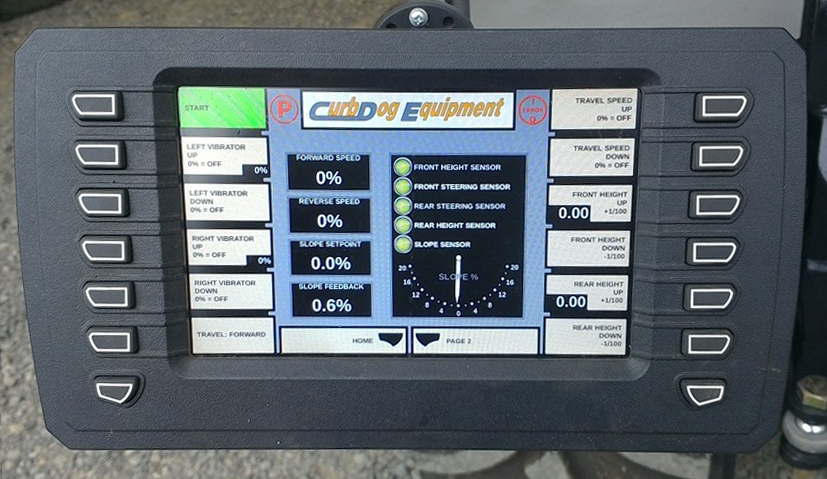

CD9700

The true bad-boy of our curb machines line …Under 10,000 pounds, yet capable of curbing and paving at dimensions equal to machines 3 times it’s size! Includes 24” x 72” Retractable Grading Auger and the iTerra™ Digital Controller

Definition

Understanding Slump

Slump is a measurement of the workability or consistency of concrete. In other words, it measures how easy the concrete is to push, mold and smooth out. Accordingly, its slump rating indicates what construction application the concrete is good for. The higher the slump, the more workable the concrete. If the slump of concrete is too low, it won’t shape very easily. If it is too high, you run the risk of having the gravel, sand and cement settle out of the mixture, making it unusable.